2PM series circular electrical connectors mainly adopt Russian connector technology.It is widely used for electrical connection and signal transmission between electrical equipment in railway system,trams and trolley bus etc.Its unique structure can make up for the shortcomings of many other similar connectors,making it more convenient and scientific to use.The cable plug and panel socket are threaded connection.The panel socket also has a glass sintered sealed socket (M) and a glass sintered sealed bulkhead socket (C),which can simultaneously meet the user equirements inspecial environments such as vacuum,sealing,and high temperature.It can be matched and interchanged with original parts of Russian2PM(T) /2РМД(T) /2РМГ/2РМГД /2РМГП/2РМГПД series.

Technical characteristic:

Connector type: Cable plug /panel socket

Orentation: Straight/Angled

Connection method: Thread connection

Shell Material: Aluminum alloy

Contact Material: Copper with silver/gold plated

Shell Size: 2PM14/18/22/24/27/30/33/36/39/42/45

Contacts: 4/7/8/10/19/20/22/24/32/45/50

Termination: Solder

Mating Cycles: 500 times

Working Voltage: ≤700V

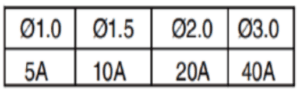

Working Current: 5-40A

Insulater: Bakelite(Glass fiber mixed) /PBT

Operating temperature: -60℃ – +200℃

Insulation resistance: Normal ≥1000MΩ Moistheat ≥20MΩ

Contact resistance: 0.8-5mΩ

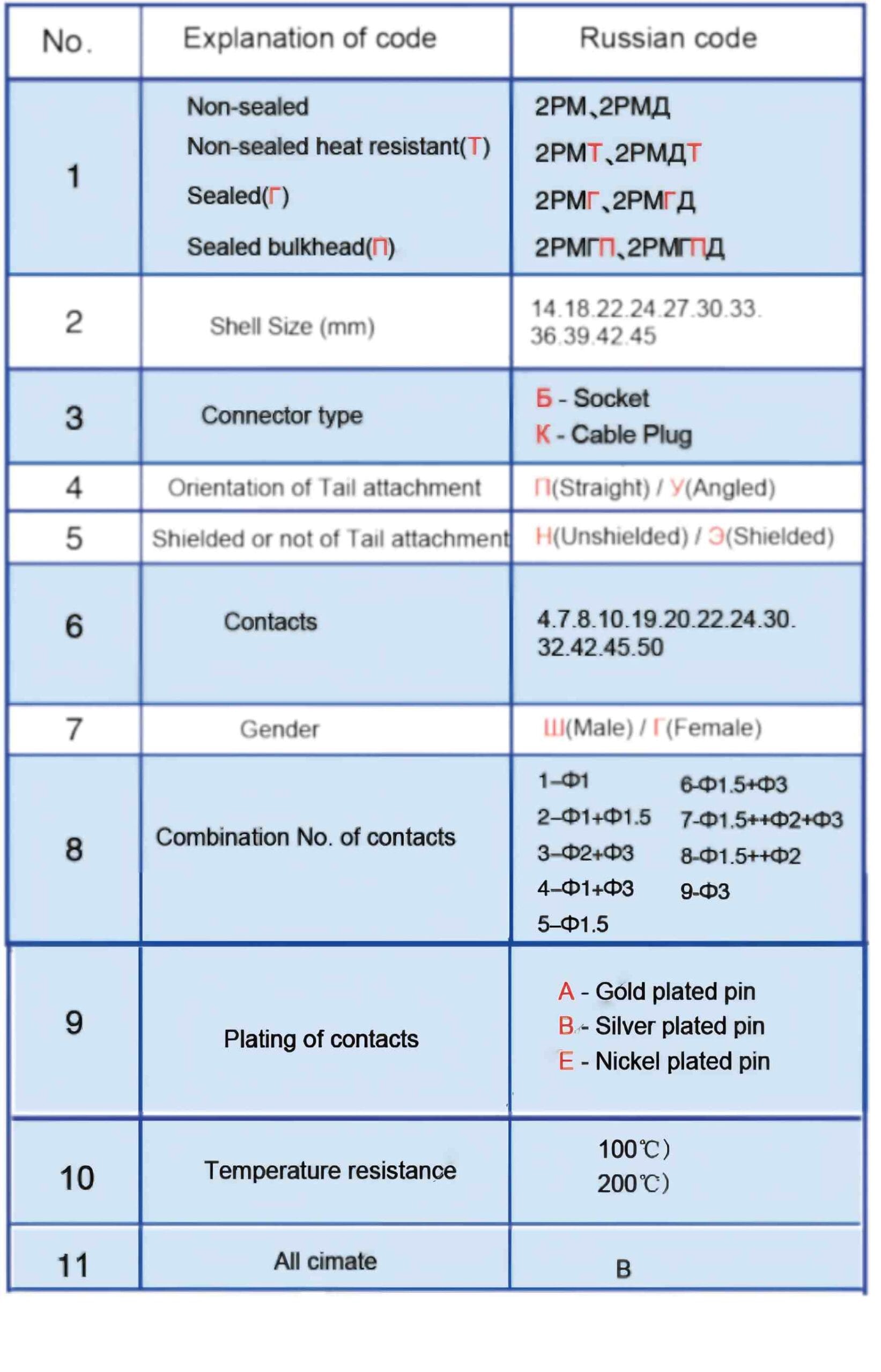

Russian/ ADWE P/N code Explanation:

Driven by continuous R&D investment, we integrate advanced manufacturing and strict quality control to ensure reliable performance in every product.

With global distribution centers and multilingual support teams, we deliver rapid response and localized technical assistance for customers worldwide.

Our full-process service ensures smooth communication, on-time delivery, and prompt after-sales response, building long-term trust with every client.

Each product undergoes comprehensive reliability testing, including high/low temperature, vibration, and salt spray evaluation, ensuring durability in harsh environments.

Yes. We can provide connector customization, pin configuration, and housing modification services according to project requirements. Our engineering team will provide professional technical support.

Absolutely. Our technical team can help identify compatible alternatives for EOL or hard-to-find parts, ensuring continuous supply for your production.

All products undergo multiple tests and reliability assessments (high and low temperatures, vibration, salt spray, etc.) and strictly adhere to ISO and RoHS standards.

MOQ varies depending on the product type. Some commonly used models support small-batch trial orders.