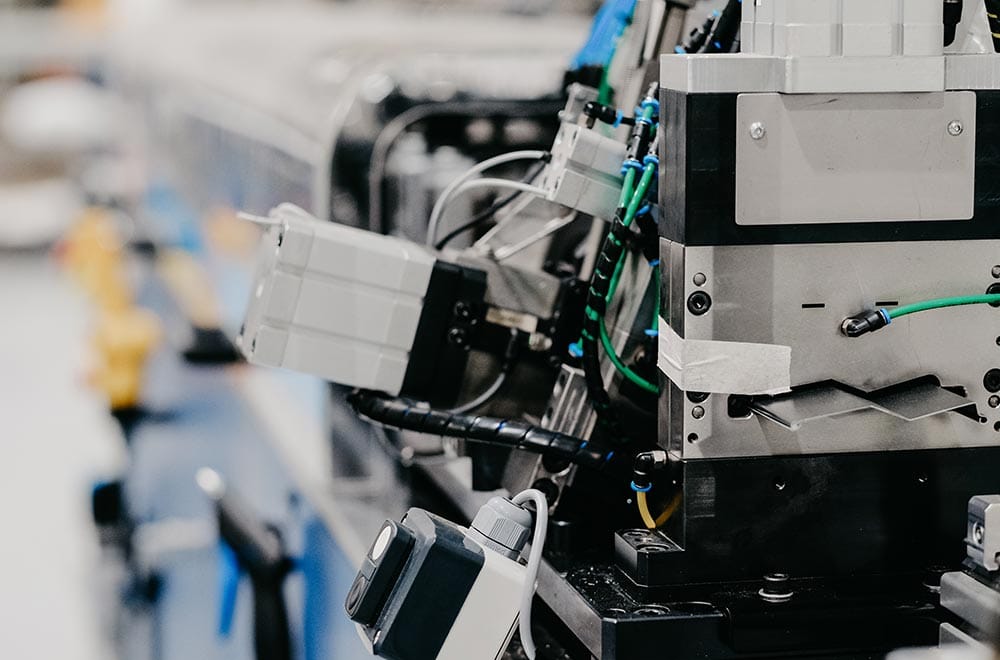

With the accelerated implementation of Industry 4.0 and smart manufacturing, the connection density, data transmission stability, and environmental adaptability of factory equipment have become particularly critical. As one of the core interfaces, circular connectors (M series, L series) continue to expand in industrial automation.

The reasons for the popularity of circular connectors include:

· Higher protection ratings (IP67/IP68)

· Stronger electromagnetic interference resistance

· Rugged and durable structure

· Support for mixed signal/power transmission

· Quick plugging and unplugging, easy maintenance

On equipment such as robotic arms, production line vision systems, AGV logistics vehicles, and CNC machine tools, circular connectors provide stable power, signal, encoder feedback, and communication connections.

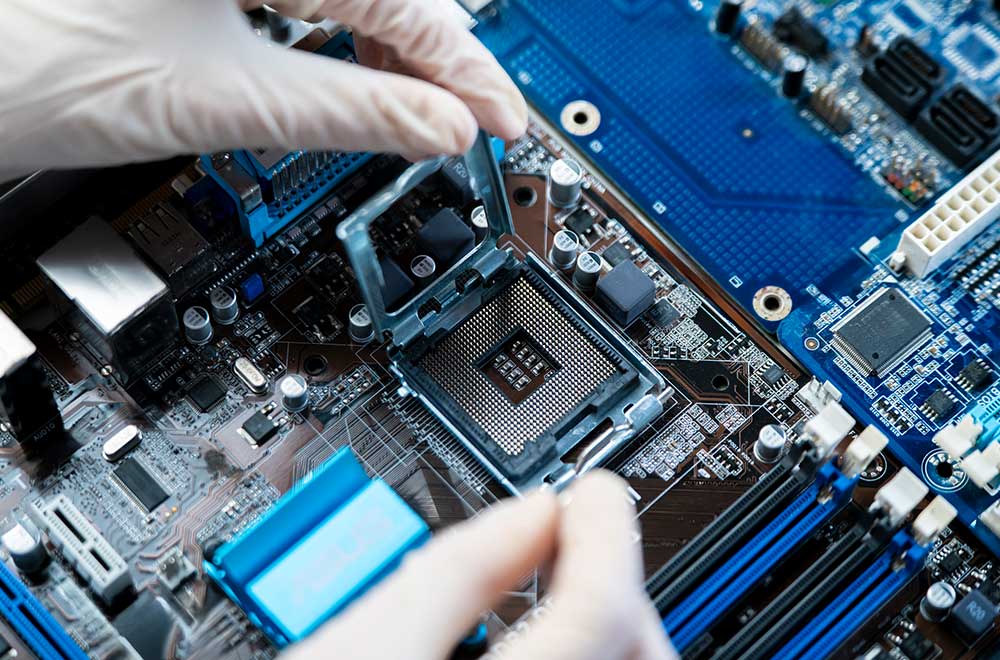

It is worth noting that industrial automation’s OT (operation technology) networks are evolving towards higher speeds and greater reliability, leading to three trends in connectors:

① High Speed:

As industrial Ethernet applications expand, data ports need to support high-frequency transmission, requiring higher standards for signal terminal materials and shielding structures.

② Miniaturization:

The more intelligent the equipment, the more precious the internal space; the demand for small connectors such as M8 and M5 is rapidly increasing.

③ Modular Design

Power/signal/data modules can be flexibly combined as needed, improving design flexibility.

Industry experts point out that driven by the popularization of smart factories and the networking of industrial sites, circular connectors will continue to maintain rapid growth in the next five years.